-

Ten Common Problems In CNC Machining Process

Starting from the actual production, this article summarizes the common problems and improvement methods of CNC machining process, and how to choose the three important factors of speed, feed rate and cutting depth in different application areas for your reference.

2021-10-09

-

The Standards List For Mold Manufacturing Acceptance

120 standards for mold acceptance, including special-shaped product appearance, size, fit, mold appearance, mold material and hardness, demolding, resetting, core pulling, participation, cooling and heating system, pouring system, molding parts, parting surface, exhaust Groove, injection molding production process, mold packaging and transportation, etc.

2021-10-11

-

The Commonly Used Functions Of Several Washers

There are many types of washers, different sizes and thicknesses, and different materials, and their roles are different. Now the functions of several commonly used washers and installation precautions are introduced to you.

2021-10-30

-

The Difference Between Mechanical Keyboard Shaft

As more and more people love e-sports, people have higher and higher requirements for mechanical keyboards. For example, mechanical keyboards have become the first choice of many users. These mechanical keyboards are divided into mechanical keyboard axes with many colors. Some people can't help but ask what is the difference between these mechanical keyboard axes?

2021-10-16

-

Comprehensively Master The Skills In Drilling And Cnc Machining Practice!

The correct use of coolant is essential to obtain good drilling performance, it will directly affect the chip evacuation, tool life and the quality of the machined hole during machining.

2021-10-09

-

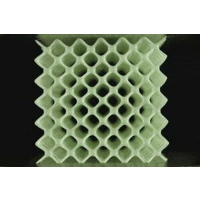

The development of additive polymers helps traditionally manufactured parts turn to 3D printing

As additive manufacturing (AM) becomes more and more common in manufacturing, many traditional manufacturers are considering applying it to certain applications even in high-volume environments. However, jumping into a whole new field of manufacturing can be daunting, and it will be much easier with the guidance of experienced personnel.

2021-10-30

-

What should I do if bubbles appear in injection molding?

One of the main causes of defects in cosmetic molded parts is air bubbles. This troublesome part defect not only causes appearance problems, but also damages physical properties. Bubbles are a common phenomenon, but they are usually difficult to resolve.

2021-10-30

-

How do plastic processing companies respond to digital transformation?

Recall that in January last year, the economy was booming, machines were running day and night, and our biggest worry was how to find more labor. However, less than 12 months later, a whole new set of priorities and concerns emerged.

2021-10-30

-

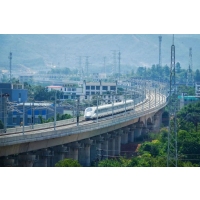

High-speed rail is made of aluminum alloy

Rail transit mainly includes railway passenger cars, freight trains, high-speed trains, subways, light rails, and maglev trains. What I want to focus on here is the high-speed train, which is what we often call the high-speed rail. China's high-speed rail manufacturing and operation technology can be said to have reached the world's leading level.

2021-10-09

-

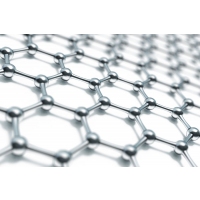

New research finds ways to improve the properties of graphene materials

A new study found that the purity of graphene may be an obstacle to the wide application of this new material. Reducing silicon pollution in graphene is expected to improve its performance and give full play to the application potential of graphene in the industry.

2021-10-09

-

What Is PBT Material?

Pbt material is an engineering material with excellent performance, with excellent toughness and fatigue resistance, good heat resistance, weather resistance, good electrical properties, and low water absorption. The modified pbt material is to be modified by strengthening and flame retardant, so as to improve its heat resistance, flame retardancy, dimensional stability and modulus, and is used in automobiles, electronic and electrical industries.

2021-10-09

-

Key technologies for the synthesis and application of functional hyperbranched polymers

The wind power industry is a basic industry for the country's sustainable, green and healthy development, and high temperature resistant insulating resin is the key material to ensure the long-term stable operation of wind turbines

2021-10-16

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material