-

The added value of the automotive bearing industry will increase by an average annual rate of 7%

The income from main business has increased by 6% annually. Among them, the average annual growth rate of high-end automotive bearing business revenue is set to 15%, and the average annual growth rate of low-end automotive bearing business revenue is set to -2%.

2021-11-13

-

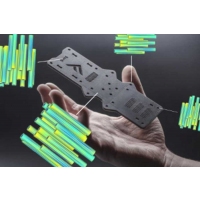

Four Ways To Achieve Lightweight 3D Printing

The advantages of lightweight structure are not difficult to understand. Taking a car as an example, lighter weight can bring better handling, and the power output by the engine can produce higher acceleration. Because the vehicle is light, the acceleration performance is better when starting, and the braking distance when braking is shorter. Take airplanes as an example. If the weight becomes lighter, the fuel efficiency and load capacity can be improved.

2021-11-20

-

China's current high-end mold market satisfaction rate is less than 60%

The advantages of China's cheap labor costs and the continued and rapid development of the overall economy have brought bright development prospects to the Chinese mold industry. It is expected that by 2018, China will become one of the world's largest mold manufacturing bases.

2021-11-20

-

Three factors restrict the development of China's injection mold industry

In recent years, China's injection molds have developed rapidly in terms of quality and quantity. However, compared with foreign advanced technologies, the technical standards of most Chinese enterprises still need to be improved. At present, compared with foreign advanced technology, China's injection mold industry mainly has the following problems.

2021-11-06

-

China's automotive mold development prospects are broad

The rapid development of China's automobile industry has brought a broad development space for domestic automobile molds. In addition, due to cost and market factors, the focus of mold manufacturing in developed countries has gradually shifted to developing countries represented by China.

2021-11-20

-

Is It Better To Use "Steel" Or "Aluminum" For Automobile Materials

Whether it is better to use "steel" or "aluminum" as the material for the car has caused an uproar in the luxury car market. The origin of the incident is: Mercedes-Benz’s new E-Class is accused of different domestic and foreign standards. Unlike the overseas version of the Mercedes-Benz E-Class, the domestically-made new long-wheelbase E-Class has changed the aluminum covering parts that were originally used in many places. Steel material.

2021-11-13

-

What are the precautions for sinker EDM?

The successful operation of sinker EDM depends on the understanding of the relationship between each spark, electrode and workpiece.

2021-11-01

-

Adjusting additives in composite materials can improve 3D printed part properties

From Kevlar fiber to artificial wood flooring, there are composite materials everywhere. They are strong, dimensionally stable, wear-resistant and corrosion-resistant.

2021-11-01

-

Brass processing can optimize and save working time and money

Doug Coster (Doug Coster) will use brass to manufacture all parts, because this material has excellent machinability. The Koster plant has significantly reduced cycle time. Nolte Precision Manufacturing Co., in Cincinnati, Ohio, cooperated with manufacturing technology companies to achieve TechSolve's work involving brass fittings.

2021-11-01

-

How to combine pressure and power in waterjet cutting to maintain the best cutting performance?

Since the use of waterjet technology 50 years ago, there has been a debate about how the combination of pressure and power can achieve the best cutting performance. How to get better or faster cutting? Which combination of pressure, horsepower, and nozzle assembly is best for a specific application? Next, the editor of Xianji.com will take everyone to learn together.

2021-11-01

-

How to analyze the binding force of wire drawing in sheet metal wire drawing operation?

In recent years, automobile parts are increasingly made of aluminum alloy, high-grade and ultra-high-strength steel, which have excellent structural properties and lightweight characteristics. However, compared with commonly used low carbon steels, the formability of these materials is more restricted.

2021-11-01

-

Increase productivity and reduce downtime of welding operations

Robotic gas-shielded metal arc welding (GMAW) welding guns and wearing parts are an important part of the welding operation, but they are often overlooked when investing in robotic welding systems. In fact, buying high-quality GMAW robot automatic spray guns and consumables can save significant costs in the long run, so companies usually choose the cheapest price.

2021-11-01

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

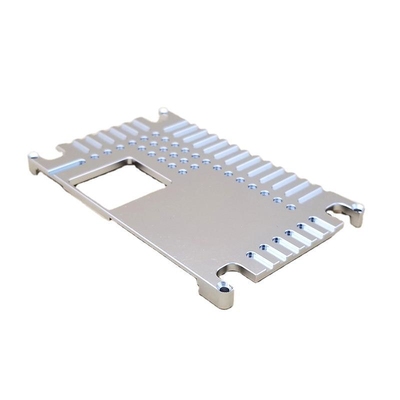

- LED Heatsink

- Building Parts

- Mobile Parts

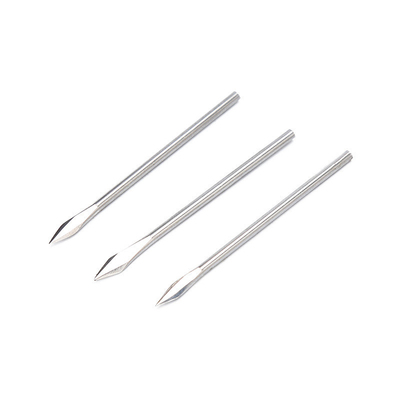

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material