-

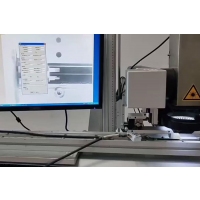

The Commonly Used Inspection Tools List For Cnc Machining

After machining, the workpiece must be inspected accordingly. In the inspection, in addition to knowing the inspection standards for machining, we should also know what are the commonly used inspections for machining?

2021-11-13

-

How To Measure Cnc Machining Accuracy

The machining accuracy of machining is the degree of conformity between the actual size, shape and position of the three geometric parameters of the workpiece surface after machining and the ideal geometric parameters required by the drawings provided by the customer.

2021-11-20

-

How To Choose Blanks Material For Cnc Machining?

When performing machining, the selection of blanks not only affects the economics of blank manufacturing, but also affects the economics of machining. Therefore, when selecting blanks, both mechanical processing and economic factors must be considered. How to choose the blank material for machining?

2021-11-20

-

The Application Of Sensor Technology In CNC Machining Process

With the development of the times, more and more intelligent, in the traditional processing industry such as precision mechanical parts processing, there are also many modern high-tech applications. The purpose of sensing detection in the machining and cutting process is to optimize the productivity, manufacturing cost, or (metal) material removal rate of the cutting process.

2021-11-20

-

Smart Manufacturing Promote The Digital Transformation Of The Industry

During the "14th Five-Year Plan" period, to achieve the improvement of manufacturing quality and efficiency, maintain the basic stability of the manufacturing industry, and improve the modernization level of the industrial chain, the key means of intelligent manufacturing is still inseparable.

2021-11-20

-

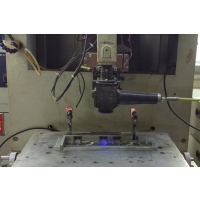

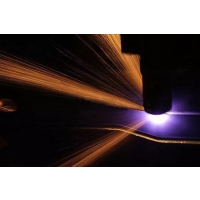

The Difference Between Laser Welding And Robot Welding

What is the difference between laser welding technology and robot welding? With the continuous development of welding technology, various welding processes have begun to develop. Among them, laser welding technology is widely used in various fields

2021-11-20

-

Precision Bearings Are Important Parts In Machine Tool

Precision bearings are one of the important parts in the operation of machine tool equipment. In the CNC machine tool industry, precision bearings have always played an important role in normal operation and production efficiency.

2021-11-20

-

Common Metal Processing Technology List

Metal processing technology includes turning, milling, planing, grinding, clamp, wire cutting, CNC machining, heat treatment, forging, casting, electric spark, stamping, die-casting, etc.

2021-11-13

-

The Development Of Intelligent Auto Parts Mould

For the development of the industry, the market is the top priority, and the better development of the market can most directly reflect the good or bad of the industry trend. At present, with the improvement and improvement of various aspects, my country's auto parts mold industry has been on the right track and is developing in a higher direction.

2021-11-20

-

Aluminum Is Important Application Field For Materials Energy Saving And Emission Reduction

To achieve sustainable development in the aluminum life cycle, the aluminum industry involves a series of sectors such as bauxite, alumina, carbon electrodes, power supply, electrolytic aluminum, aluminum processing, and waste aluminum recycling. It is a resource and energy-intensive industry.

2021-11-06

-

How 3D Printing Technology Is Applied In The Auto Parts Industry

At present, the production technology and manufacturing standards of my country's auto parts industry cannot meet most of the requirements of automakers. Almost all core technologies are monopolized by multinational companies. It seems that technological innovation is still far away

2021-11-13

-

The Popularization Of Robot Foundry Applications

Since the first industrial robot appeared in the 1960s, it has been constantly updated and tested. Industrial robots integrate advanced technologies such as machinery, electronics, and computers. In the manufacturing process, industrial robots have greatly promoted the process of manufacturing automation.

2021-11-20

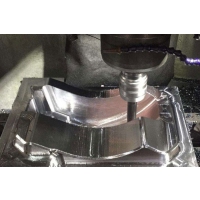

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material