-

The Certification Marks And Term Explanations Of Industrial Computers In The World

Industrial PCs in China generally have 3C certification, CE certification and CQC certification. The most basic is the 3C certification, which is China's mandatory electrical and electronic standards. For the certification mark of industrial computer, each national standard is different. I will explain to you what other certifications are available for industrial computers

2021-11-20

-

The Comparison Of Industrial Computer Chassis Types

The use environment of the industrial computer chassis is generally harsh, high temperature, low temperature, high humidity, long-term uninterrupted operation, and places with more gray noise. Therefore, the protection requirements for the industrial computer chassis are very high.

2021-11-08

-

Our Industrial Computer Sometimes Very Hot In Use?

After receiving our industrial computer, many customers will conduct a systematic test on it, such as running a program, turning the CPU to the maximum and the memory to the maximum, they will find that the external casing of the industrial computer will be very hot. What is the reason for the high heat output of the industrial computer?

2021-11-20

-

How To Quickly Own CAN Bus In Industrial Computer

Due to industries such as high-speed rail, subway, and aerospace, industrial computers are required to have a CAN bus. Because the price of CAN bus interface is high or low, many industrial computer manufacturers with standard interface do not have CAN bus.

2021-11-08

-

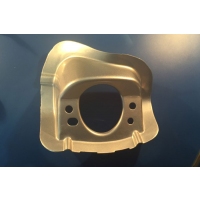

Industrial Personal Computer Case Production Structure

Industrial Personal Computer, also known as industrial computer host, is a hardware assembly that integrates industrial motherboards, CPUs, memory, motherboards, hard drives, I/O input and output interfaces, and is more robust and stable than commercial computers in terms of production structure and performance

2021-11-13

-

3D Printing Enhances The Added Value Of Injection Mold Manufacturers

For mold manufacturers, since the quality of the mold directly determines the efficiency of injection molding production and the quality of the product, which determines the added value of the product, how to efficiently cool plastic products in the minimum cycle time becomes a conformal cooling mold design and manufacturing A key consideration in the process, and cooling plays an important role in this.

2021-11-20

-

Lightweight Automotive Mold Production Is Coming

Reducing the weight of the car is what people have been pursuing and exploring. Lighter cars can improve vehicle performance on the one hand, and on the other hand, it can better meet the needs of energy conservation and environmental protection.

2021-11-07

-

How ToTreat This Round Of Non-Ferrous Metal Price Increase?

Therefore, there is an objective requirement for upward restoration. On the other hand, there is no lack of speculative capital in the price increase of non-ferrous metals, which has caused prices to rise too fast and excessively, which has an adverse effect on China's economy.

2021-11-07

-

The Advantages Of Laser Cutting Technology In The Mold Field

In recent years, the mold industry has developed rapidly, and traditional processing methods are far from being able to meet the current development situation, and transformation and development are imperative. The advantages of laser applications in the mold industry have become increasingly prominent.

2021-11-13

-

The Application And Development Of Vacuum Coating Technology In China

Vacuum coating technology is a novel material synthesis and machining technology, and it is an important part of the field of surface engineering technology. With the rapid development of the global manufacturing industry, the application of vacuum coating technology has become more and more extensive.

2021-11-07

-

The Impact Of Cloud Computing On China's Mold Manufacturing Industry

Cloud computing provides dynamic, easily scalable and often virtualized resources through the Internet. Cloud computing can greatly reduce the cost of informatization, promote the popularization and application of information technology, and promote the extensive integration of industrialization and informatization, which is another revolution in the field of information technology.

2021-11-27

-

Solve The Development Problems Of The Foundry Industry

Since the "Twelfth Five-Year Plan", China's foundry industry has continued to develop steadily, but the growth rate has slowed down significantly. Like other industries in the national economy, it has entered a new normal of development.

2021-11-13

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material