-

The Application And Development Of Vacuum Coating Technology In China

Vacuum coating technology is a novel material synthesis and machining technology, and it is an important part of the field of surface engineering technology. With the rapid development of the global manufacturing industry, the application of vacuum coating technology has become more and more extensive.

2021-11-07

-

The Impact Of Cloud Computing On China's Mold Manufacturing Industry

Cloud computing provides dynamic, easily scalable and often virtualized resources through the Internet. Cloud computing can greatly reduce the cost of informatization, promote the popularization and application of information technology, and promote the extensive integration of industrialization and informatization, which is another revolution in the field of information technology.

2021-11-27

-

Solve The Development Problems Of The Foundry Industry

Since the "Twelfth Five-Year Plan", China's foundry industry has continued to develop steadily, but the growth rate has slowed down significantly. Like other industries in the national economy, it has entered a new normal of development.

2021-11-13

-

China Terminal Molds Lead The Terminal Blocks Development

In recent years, the domestic terminal mold industry, as a member of the mold industry, has many products sold globally, but profits have been hovering at a low level. The most infuriating and even helpless thing is that many products have no difference in quality compared with similar foreign products, but the unit price is much higher than that of domestic terminal mold products, making it difficult for many domestic products to enter some high-end markets.

2021-11-27

-

The Measures To Improve Stamping Dies Durability

Improving the durability of stamping dies is very important. Stamping dies are necessary process equipment in the stamping production process, which play a decisive role in improving product quality, extending product life, and improving production efficiency.

2021-11-13

-

The Trend Of CNC Machining Mobile Phone Metal Case

Beginning in the second half of 2015, some people have predicted through data analysis that CNC machining of metal casings for mobile phones in China has overcapacity. Due to the failure rate of CNC machining and the unbalanced distribution of orders between large and small processing plants, the prediction result may be too early

2021-11-13

-

The Effect Factor Of CNC Swiss Machine Accuracy

Numerically controlled swiss machine is affected by the change of workshop environment temperature, motor heating and mechanical movement friction heating, cutting heat and cooling medium, resulting in uneven temperature rise of each part of the machine tool, leading to changes in the machine tool shape accuracy and machining accuracy.

2021-11-06

-

Introduction To The Performance Of Alumina Ceramic Materials

Among oxides with a melting point of more than 2000°C, alumina ceramics is the most flexible and cheap material. Alumina ceramics is a ceramic material with alumina (alumina) as the main body. Alumina ceramics have high mechanical strength, high hardness, low high-frequency dielectric loss, and because of its wide source of raw materials, relatively cheap prices, and mature processing technology, it is widely used in electronics, electrical appliances, machinery, textiles and Aerospace and other fields.

2021-11-06

-

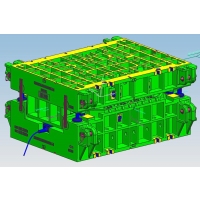

Development and Application of Spray Technology in Die Casting Mould

The good spraying effect of mold lubricant is the key factor to obtain good casting surface quality. However, the existing spraying methods often fail to take into account the entire cavity surface, and there are often cases of poor spraying, local mold sticking, and strains.

2021-11-06

-

How To Choose 3D Printer?

Whether for personal, professional or educational purposes, 3D printers are more affordable than ever. Check out what you need to know about the technology to start printing, as well as the highest performing model in our official testing.

2021-11-06

-

What Are The Requirements For Spray Coating To Achieve Wear Resistance?

Under normal circumstances, the customer's requirements for wear-resistant coatings depend on the mechanical compatibility of the wear-resistant coating with the base material, the direction and size of the applied load, and the performance of the coating itself. Depending on the application of wear-resistant coatings, Xionghui Electronics' coating hardness, chemical stability, coating strength and other factors all affect the wear resistance of the coating.

2021-11-06

-

The Metal Forming Method Of Casting

The liquid metal is poured into a mold cavity suitable for the shape and size of the part, and it is cooled and solidified to obtain the production method of the blank or part, which is usually called liquid metal forming or casting.Process flow: liquid metal→filling→solidification shrinkage→casting

2021-11-06

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

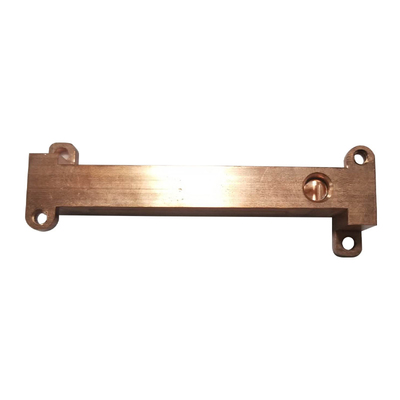

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material