-

The difference between metal plating and plastic plating

Electroplating is the process of using electrolysis to attach a metal film to the surface of metal or other materials to prevent metal oxidation (such as rust) and improve wear resistance, conductivity, light reflection, and corrosion resistance (copper sulfate, etc.) And to enhance the beauty and so on. So, do you know about metal electroplating and plastic electroplating? What is the difference between them?

2021-11-09

-

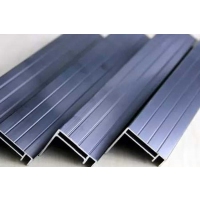

Introduction of aluminum surface treatment technology

Aluminum is usually processed into castings, forgings, foils, plates, strips, tubes, rods, profiles, etc., and then cold bending, sawing, drilling, assembling, and coloring. The main metal element is aluminum, and some alloying elements are added to improve the performance of aluminum. What is the technical process for surface treatment of aluminum?

2021-11-09

-

Failure analysis in the heating process of thermal surface treatment

Surface heat treatment is a metal heat treatment process that changes the mechanical properties of the surface layer by heating and cooling the surface of the steel part.

2021-11-09

-

Anti-rust and anti-tarnish measures for electroplating equipment

The equipment used in the electroplating process mainly includes various fixed tanks, barrel plating tanks, hangers, hanging baskets, etc. The following introduces the anti-rust and anti-tarnish measures of electroplating equipment.

2021-11-09

-

Pretreatment requirements for valve assembly

A valve is a mechanical device that controls the flow, direction, pressure, temperature, etc. of the flowing fluid medium. The valve is a basic component in the pipeline system. This article mainly introduces the specific requirements for pre-treatment of valve assembly.

2021-11-09

-

Surface treatment method of screw fastener

Screw fasteners are the most widely used mechanical basic parts and are in great demand. Surface treatment is the process of forming a covering layer on the surface of the workpiece through a certain method. Its purpose is to give the product surface a beautiful and anti-corrosion effect. The surface treatment methods carried out are attributed to the following methods:

2021-11-09

-

What are the requirements for screw fastener plating?

Electroplating is a common method of surface treatment for hardware screws and other fastener products. Under normal circumstances, the quality of electroplating is mainly measured by its corrosion resistance, followed by appearance. Corrosion resistance is to imitate the working environment of the product, set it as the test condition, and conduct a corrosion test on it. The quality of electroplating products is controlled from the following aspects:

2021-11-09

-

Process Control of Aluminum Alloy Extinction Electrophoresis

Electrophoresis has been increasingly widely used in various fields such as analytical chemistry, biochemistry, clinical chemistry, toxicology, pharmacology, immunology, microbiology, and food chemistry. The matte electrophoretic coating of aluminum alloy is applied on the surface of the anodic oxide film.

2021-11-09

-

Inventory of 3D printed plastic black technology

With the continuous research and development of new technologies, "3D printing" has become more and more widely used, such as industrial design, dental and medical industries, construction engineering, information systems, aerospace, etc. 3D printing has slowly penetrated into all aspects of our lives. Bring us convenience and reduce costs.

2021-11-09

-

Development and Application of Online Thickness Measurement System for Galvanized Sheet

Galvanized steel sheet is to prevent corrosion on the surface of the steel sheet and prolong its service life. The surface of the steel sheet is coated with a layer of metal zinc. This kind of galvanized steel sheet is called galvanized sheet. Galvanizing is an economical and effective anti-rust method that is often used. About half of the world's zinc production is used in this process.

2021-11-09

-

New technology of zinc-nickel alloy wastewater treatment

Electroplating zinc-nickel alloy refers to the formation of a coating film on the surface of the plated parts at a ratio of zinc to nickel 9:1. This protective coating has developed rapidly in recent years due to its excellent corrosion resistance and is widely used in automobiles, aviation, electronics and other industries.

2021-11-09

-

Introduction of hot-dip galvanizing and its advantages

Hot-dip galvanizing (hot-dip galvanizing) refers to the method of immersing the plated fasteners in liquid metal zinc or its alloy for plating. Hot-dip galvanizing is widely used to protect steel and its parts from atmospheric corrosion, and is especially suitable for mass production of standard parts and fasteners.

2021-11-09

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material