-

Application of energy-saving heat treatment technology and equipment in the bearing industry

For small and miniature precision bearings, the chemical composition of raw materials, original organization, machining level, heat treatment process, and processing equipment may greatly affect the service life of the bearing. This article mainly talks about my personal views from the aspects of vacuum heat treatment process and equipment. Please criticize and correct any improprieties.

2021-11-13

-

Vacuum heat treatment technology for precision bearings

For small and miniature precision bearings, the chemical composition of raw materials, original organization, machining level, heat treatment process, and processing equipment may greatly affect the service life of the bearing. This article mainly talks about my personal views from the aspects of vacuum heat treatment process and equipment. Please criticize and correct any improprieties.

2021-11-13

-

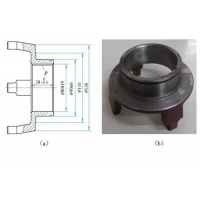

Heat treatment process of thin-walled guide sleeve

A guide sleeve is installed in the central transmission of the new full-hydraulic bulldozer produced by our company. This part cooperates with the flange plate to play a guiding and fixing role.

2021-11-12

-

Add additional functions of die-casting machine to meet the needs of die-casting process

Introduction: As the basic technical equipment of die-casting, die-casting machine has a great impact on product quality, production cost, production efficiency, etc. during the production process.

2021-11-12

-

How to improve the stability of fast injection of domestic die-casting machine

The production of die-casting parts requires die-casting machinery and equipment. Die-casting machines are the basis for the production of die-casting parts. The technical level of die-casting equipment determines the quality and level of die-casting parts.

2021-11-12

-

Common faults and solutions of low pressure casting machine

The principle of the low-pressure casting machine is mainly to fill the sealed protective furnace with a certain amount of dry compressed air. Under the action of air pressure, the metal liquid in the holding furnace will flush the mold cavity along the riser pipe to make the metal liquid in the mold cavity.

2021-11-12

-

Talking about the development and application of automobile casting process and casting technology

At present, the production technology of automobile castings in developed countries in the European and American automobile industries is advanced, with good product quality, high production efficiency and low environmental pollution.

2021-11-12

-

Application Analysis of Casting Production Technology of Pump Body Castings

The dredging pump is a professional pump used in the dredging industry recently. The flow parts are mainly made of wear-resistant steel and Hangmo white cast iron. The pump casing is the main part of the dredging pump, and it is also its largest wear-resistant material casting.

2021-11-12

-

The influence of casting process on the quality of aluminum alloy castings

The influence of the casting process of the TV University of Science and Technology on the quality of aluminum alloy castings Umbrella Jingchao Gu Yuan, Wang Yanpeng, Shenyang Institute of Foundry, Shenyang Vocational and Technical College of Liaoning Equipment Manufacturing Vocational and Technical College Aluminum alloy castings with high requirements for tightness and roughness should be molded with resin sand, and a double-pack, four-riser gap-type pouring system should be adopted.

2021-11-12

-

Why does stainless steel rust?

People often think that magnets absorb stainless steel materials to verify their quality and authenticity. They are not attractive and non-magnetic. They are considered to be good and genuine; if they are magnetic, they are considered to be counterfeit products. In fact, this is an extremely one-sided and impractical method of identifying errors.

2021-11-12

-

The 3D printed bracket is compatible with multiple bicycles

The American-based Italian bicycle parts brand Silca has launched its first 3D printed bicycle product, a titanium alloy bracket named Mensola.

2021-11-12

-

Long-term anti-rust method for automobile and heavy equipment parts

Among suppliers of automotive and heavy equipment parts, short-term and long-term rust prevention is essential to prevent serious losses due to rust claims. It is also important to find an effective and easy-to-use rust inhibitor. Cortec's VpCI ® -369 is an excellent choice. It is a convenient and superior substitute for many common long-term rust inhibitors on the market.

2021-11-12

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material