-

Contribute to the expansion of additive manufacturing in aerospace and other industries that rely on strong metal parts

A research team led by Tao Tao, associate professor of materials science and engineering at the University of Virginia, made two discoveries that could expand additive manufacturing in aerospace and other industries that rely on strong metal parts.

2021-11-22

-

The cause of deadly blowholes in metal 3D printing has been found!

Laser powder bed fusion (Laser powder bed fusion) is currently the most widely used metal additive manufacturing process. Under the control of computer-aided design and drawing software, it can melt metal powder through high-power density lasers.

2021-11-22

-

What are the thermophysical properties of porous Ti2AlC and Ti3SiC2 produced by powder metallurgy?

The MAX phase is a group of ternary compounds whose general formula is Mn+1AXn (where M is a transition element, a is usually from the IIIAo IVA group in the periodic table, and X can be C or N, N=1-3). They have a nano-amination structure, which gives them unusual properties

2021-11-22

-

The introduction of ultra-lightweight stainless steel is about 20% lighter than traditional stainless steel

Recently, the Korean Materials Research Institute (KIMS) Steel Materials Research Office under the Ministry of Science, Technology, Information and Communication and the Pohang Institute of Industrial Science (RIST) have developed ultra-lightweight stainless steel for the first time in the world, which is about 20% lighter than traditional stainless steel. %about.

2021-11-22

-

New 3D printer with high-quality material printing and grade reliability

LulzBot announced the launch of LulzBot TAZ Pro S as a supplement to its TAZ Pro industrial desktop 3D printer product line. TAZ Pro S provides users with high-quality 1.75mm material printing and LulzBot's proven enterprise-level reliability.

2021-11-22

-

Improved aluminum 3D printing technology increases product hardness by 1.5 times

Scientists at NUST MISIS improved the 3D printing technology of aluminum, which increased the hardness of the product by 1.5 times. The aluminum carbon powder nano-carbon additive they developed is obtained from processing-related petroleum gas products, which will improve the quality of 3D printed aerospace composite materials. The research results were published in the international scientific journal "Composite Materials News".

2021-11-22

-

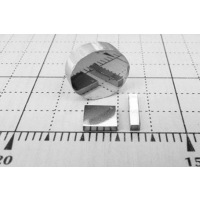

Ordinary desktop 3D printers can also print metals and ceramics

These spur gears (shown as a one-cent coin as shown in the picture above) are made of stainless steel, the quality of which meets the space standard, and only off-the-shelf desktop 3D printers are used.

2021-11-22

-

Knowledge of spin transport in thermoelectric devices helps fill such gaps

Previously, thermoelectric materials are a research hotspot, which can generate voltage in the presence of temperature differences. In terms of minimizing the use of fossil fuels and helping prevent the global energy crisis, thermoelectric energy harvesting technology is one of our best choices.

2021-11-22

-

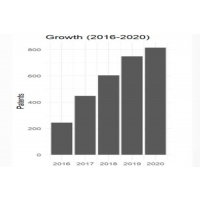

3D printing will become one of the top ten fastest-growing technologies in 2020

According to data from the US Patent and Trademark Office, the latest annual report of the IFI CLAIMS Patent Services Department has identified 3D printing as the ninth fastest-growing technology in 2020.

2021-11-22

-

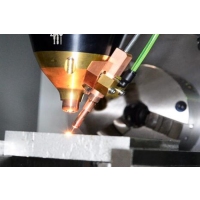

New wire feeding system for laser-based 3D printing

Hybrid Subtractive Additive System Expert Hybrid Manufacturing Technology (HMT) revealed that it will take the lead in launching a new R&D program called "FastWireAM".

2021-11-22

-

Create new 3D printing technology and integrate laser drive technology

On January 13, 2021, Washington, DC, a laser-driven polymerization process for 3D printing applications overcomes the need to build 3D printed objects at once. A research team from the Fresnel Institute in France and the Central University of Marseille in France introduced this method and used it to use quartz glass to create miniature models of bicycles and even the Eiffel Tower.

2021-11-22

-

Stereoscopic 3D printing technology connects the digital and physical worlds and realizes creative output

Joseph Coddington, a master's student at Victoria University of Wellington, has launched a project that focuses on how to use 3D printing for research methods with design focus and creative output, rather than just considering it from a technical point of view.

2021-11-22

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material