-

3D printing industry investment continues

On May 10, the reporter learned that the consulting agency Wallace released the 2019 3D printing industry annual report: The 3D printing industry scale in 2018 was 9.68 billion U.S. dollars, and it was predicted to reach 15.8 billion U.S. dollars by 2020, and it may be in 2022.

2021-12-02

-

my country's 3D printing market as a whole shows a steady and positive trend

In recent years, my country's 3D printing market as a whole has shown a steady and positive trend. More and more companies have entered the 3D printing field and hope to occupy a place in the entire 3D printing market.

2021-12-02

-

The market size will reach 5.6 billion in three years. The 3D printing market is rising in South Korea

On May 6, 2019, CCTV Finance reported on the scale of the 3D printing market in South Korea. Overall, South Korea’s 3D printing market is much smaller than China’s, but it also has a rapid growth rate.

2021-12-02

-

3D printer development software robot for custom robot equipment

Researchers created promising new robotic patent technology through Purdue Technology Commercialization Office, and outlined it in "3D Construction Soft Machine with Topologically Encoded Motion". Robot devices that can be 3D printed and customized by users have been developed, depending on their needs.

2021-12-02

-

New laser cladding alloy material project settled in Qinghai

On April 29, the first production line of the new laser cladding alloy material project was put into operation in the Qinghai National High-tech Industrial Development Zone Equipment Manufacturing Park. The project was led by the Institute of Aerospace Information, Chinese Academy of Sciences.

2021-12-02

-

New 3D printing materials increase the output of photocatalytic hydrogen production

On July 18, the reporter learned that the top journal in the field of interface materials research "ACS Applied Materials & Interfaces" published online, Dr. Yoann de Rancourt de Mimérand, a French professional teacher in the research group of Professor Guo Jia of Wuhan Institute of Technology Important research progress in the field of catalysis.

2021-12-02

-

3D printing technology releases huge market potential

The application of 3D printing technology in my country's medical industry began in the 1980s. It was initially mainly used for the manufacture of three-dimensional medical models. With the development of precision medicine and personalized medicine, the application of 3D printing technology in the medical industry has become increasingly widespread.

2021-12-02

-

The demand for high-end titanium materials is increasing and the industry is picking up

On the evening of July 16, the titanium industry leader Baoti Co., Ltd. released a performance forecast for the first half of 2019. It is expected to achieve a net profit of about 110 million yuan attributable to shareholders of listed companies, an increase of about 76 million yuan compared with the same period last year, a year-on-year increase of about 223.53%.

2021-12-02

-

The rapid development of the TPU market has a promising future

On July 12, the reporter learned that, as an industry that was once monopolized by foreign companies, my country's polyurethane elastomer industry has developed rapidly in recent years, and it has become the world's largest polyurethane elastomer market growth area.

2021-12-02

-

3D printed fiber lithium-ion battery can be used in the field of wearable electronic devices

On July 12, the reporter learned that the School of Chemical Engineering of Harbin Institute of Technology has developed a fiber lithium-ion battery using 3D printing technology. This

2021-12-02

-

PPC is expected to achieve high performance and low cost processing

On the 9th, the magazine "Angewandte Chemie International Edition" published online the latest research result of the research team of Professor Xie Xiaolin of the School of Chemistry and Chemical Engineering "Oxygen-regulated one-pot synthesis of carbon dioxide-based block copolymers" Huazhong University of Science and Technology was the first One complete unit.

2021-12-02

-

Super-hydrophobic technology on aluminum alloy surface

On July 11, the reporter learned that the team of Professor Zheng Canying from the Department of Metal Materials Engineering at Dongyi University in South Korea recently announced that the team independently developed a super-hydrophobic technology for aluminum alloy surfaces and applied for related patents.

2021-12-02

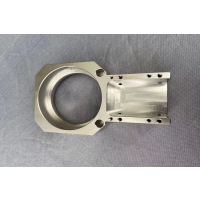

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material