-

The most promising 3D printing material - PEEK

PEKK material, the scientific name polyetheretherketone, was discovered by a US material company in the 1980s. It is a semi-crystalline, high-purity organic thermoplastic polymer with excellent strength, chemical resistance, low temperature and high temperature, and radiation resistance.

2019-09-28

-

Comparison of wear resistance between casting process and sodium silicate sand casting process

In order to make full use of the V method casting process, it is necessary to deeply understand its process characteristics, especially its limitations.

2021-11-30

-

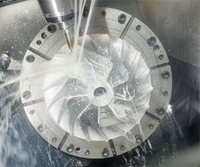

With COVID-19 Pandemic,Cnc Machining Orders Fell To The Lowest Point In 11 Years

In April 2020, the US machining industry activity fell to its lowest level in 11 years, mainly due to the severe damage to the supply chain caused by the novel coronavirus epidemic.

2021-08-12

-

Humen CNC Machining Services, Towards Mexic

Their State of the art machinery, quality craftsmanship, and attention to detail, really helped take my project to the next level. I was really impressed by the PTJ team, everyone was very knowledgeable and easy to work with.

2019-12-21

-

CNC machining robot parts in China

PTJ Shop specializes in the machining and manufacturing of robot structural parts. It has more than 30 high-speed CNC machining centers, 4 five-axis CNC machining centers, CNC vehicles, milling, engraving and cutting equipment.

2019-10-19

-

3D "weaving" technology in the field of aerospace parts

A well-known French manufacturer has developed a 3D "weaving" technique for composite fibers that combines thermoplastic resin fibers with reinforced carbon fiber weaving. When the part is cured, the thermoplastic resin becomes the matrix of the material, and the carbon fiber is also embedded therein. At present, business machine manufacturer Dassault Systèmes has used parts produced by this process on a "Falcon" business jet.

2019-09-28

-

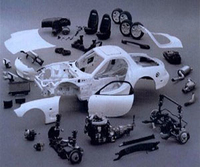

Check out the new car materials and processes born in the challenge of car lightweighting

Due to the limited space for traditional steel process optimization and the difficulty in adapting processing equipment to new body materials, the use of new materials and processes is the main way to achieve lightweight body.

2019-09-28

-

The new covering agent increases the casting production rate by 5%-8%.

Feeders are widely used in the production of large castings. How to strengthen the heat preservation of the feeder molten steel, reduce the heat dissipation rate, and extend the retention time of the molten steel is the goal pursued by the production of large steel castings.

2021-11-30

-

CNC Machining and Forming Process of Automobile Wheel Hub

The forging of automobile wheels is a change from solid to solid. The shape of the hub is formed by means of tapping, pressing, forging, etc. to CNC machining. Today, the machining process using CNC machining center is produced.

2021-03-13

-

PTJ Shop Precision Custom Medical Parts For Japanese Customer

PTJ Shop is a great company to work with. We use them anytime we have machining needs for prototypes we are working on, they are always very responsive and extremely helpful.

2019-12-07

-

What are the ways to machining plastic prototype model?

Prototype machining can reflect the designer's creativity very well. Such as the structure, the appearance of the Prototype, etc., the Prototype model allows the time to market the parts is greatly shortened, its manufacturing is forward-looking, before the mold can be developed, you can use the sample for the mall to promote, take the lead, and in the early sale, Prepare for production and occupy the market early.

2019-10-26

-

Analysis of the dilemma of adopting 3D printing in the auto parts manufacturing industry

In recent years, although news has continuously reported that 3D printing has made breakthroughs in the field of auto parts, it seems that 3D printing technology has developed extremely smoothly in the automotive industry, but in fact it is not. 3D printing technology is manufactured in the automotive industry. It is full of challenges everywhere.

2019-09-28

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material