-

What Is The Speed Of The External Thread Of The CNC Lathe?

When a CNC lathe is machining threads, due to the change of its transmission chain, in principle, its rotation speed can only ensure that the tool moves by one pitch along the main feed axis (mostly Z axis) every one revolution of the spindle, and should not be limited.

2020-01-11

-

What is the motivation for the rapid upgrading of powder metallurgy technology?

This is also the case for powder metallurgy production enterprises. Attitude is everything. Only after a good foundation and hard work can the enterprise develop better and its products can be widely welcomed.

2019-12-21

-

The starting point of powder metallurgical flow warm pressing technology

In the process of understanding powder metallurgy technology, we were exposed to the metal powder injection molding process.

2019-12-21

-

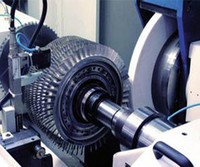

Tooth Profile Gear Machining Method Introduction

The machining of a gear consists of several processes. In order to obtain gears that meet the accuracy requirements, the entire machining process is serviced around the tooth profile machining process.

2019-12-14

-

Research on Key Technology of CNC Machining Process for Large Complex Structure of Aircraft

In the development of aviation technology, the requirements for large-scale, integrated, thin-walled, and precise aircraft structural parts are very prominent.

2019-11-16

-

Machining Characteristics And Material Selection Method Of Cold Deformed Mold Steel

With the development of the mechanical machining industry, more and more parts are produced by cold work dies in production, and more and more types of cold deformation dies are used.

2020-01-11

-

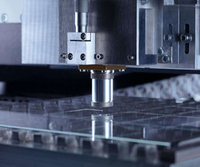

The Status And Prospect Of Laser Precision Machining Technology

Laser material machining involves a wide range. Sintering, punching, marking, cutting, welding, surface modification and chemical vapor deposition of materials have all taken laser as an indispensable energy source.

2019-12-28

-

Detailed Examples Of Shaft Machining Technology

The formulation of the process specifications in the shaft parts is directly related to the quality of the workpiece, labor productivity and economic benefits.

2019-11-16

-

Detail Definition of 1137 Tempered Steel

Nickel alloy containing 50 (at)% titanium. The recovery temperature is 70 ° C, and the shape memory effect is good. A small change in the nickel-titanium composition ratio can change the recovery temperature in the range of 30 to 100 ° C.

2020-01-04

-

Application Of Laser Machining In Machinery Manufacturing

The core of laser processing technology is the interaction between the laser beam and the material. It is divided into laser thermal processing and photochemical reaction machining according to different machining methods.

2019-12-21

-

Ways To Improve The Accuracy Of Shaft Gear Hobbing

Through the analysis of the machining accuracy of the shaft gear hobbing, the factors affecting the machining accuracy of the hobbing are found out, so as to improve the quality of the hobbing processing.

2019-11-23

-

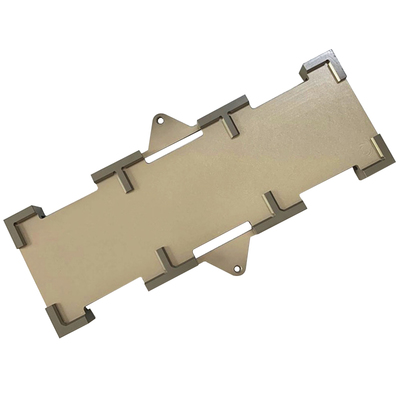

3 Application Methods of Aluminum Profile Machining in Aviation Industry

As the aviation industry becomes more powerful and the competition is fierce, in the case of seeking word of mouth, the aviation parts themselves must be securely put in place.

2019-12-07

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material