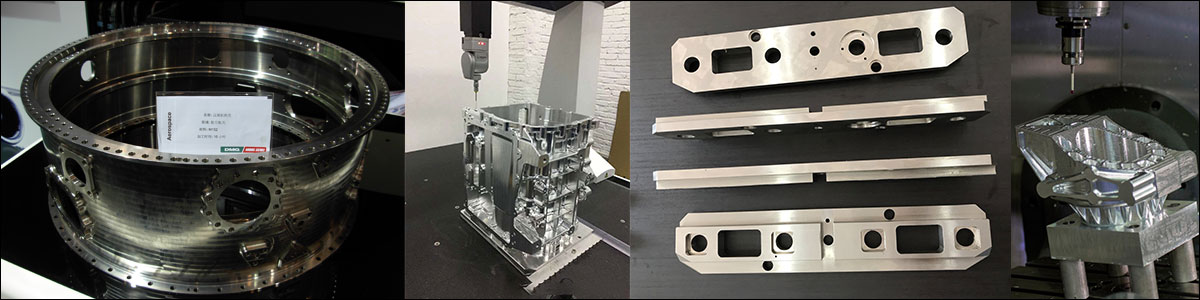

PRECISION BERYLLIUM C17300 MACHINED PARTS

non-standard beryllium copper 173 parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from Beryllium Copper 173. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. Beryllium Alloy 173 is a kind of wear-resistant copper with excellent hardness, excellent electrical conductivity and good anti-tempering ability. It has good erectability and is not easy to bend. It is a good aeronautical material processing electrode. Beryllium Alloy 173 has good electrical conductivity, thermal conductivity, high hardness, wear resistance, burst resistance, high cracking resistance and softening temperature, low electrode loss during welding, fast welding speed and low total welding cost. It is suitable as the electrode of fusion welding machine. Regarding the fittings, but the performance of the plated workpieces is average. BeCu 173 has a machining cost factor of 1.0 when compared to steel 12L14, making it a better economic choice than BeCu 172. It is good for soldering, brazing, welding, and hot and cold working, but is not ideal for forging. BeCu can be annealed. |

|

|

|

|

|

|

|

|

|

Contact our beryllium C17300 Machining services machinists today to discuss the specifics of your complex parts. |

Beryllium Copper Alloy 173 Machining Industries & Applications

- ▶ Electrical contacts

- ▶ Valve components

- ▶ Fasteners

-

▶ Pump components

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminium, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;